Leading supplier of morse products

- Band Saw Blades

- Portable Bandsaw Blades

- Aldi Portable Bandsaw Blades

- Bosch Portable Bandsaw Blades

- Cutmax Portable Bandsaw Blades

- Dewalt Portable Bandsaw Blades

- Femi Portable Bandsaw Blades

- Makita Portable Bandsaw Blades

- Metabo Portable Bandsaw Blades

- Milwaukee Portable Bandsaw Blades

- Scheppach Portable Bandsaw Blades

- Stout Portable Bandsaw Blades

- Porter-Cable Portable Bandsaw Blades

- Circular Saw Blades

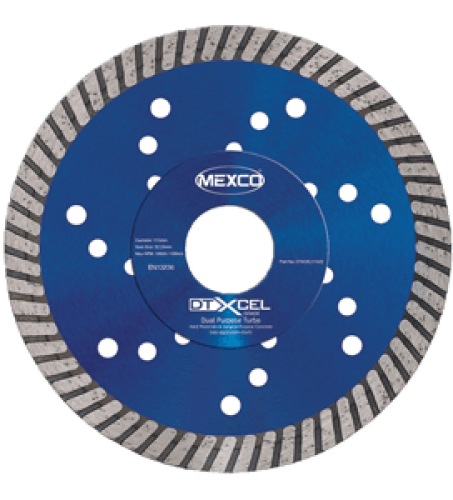

- Diamond Blades & Drills

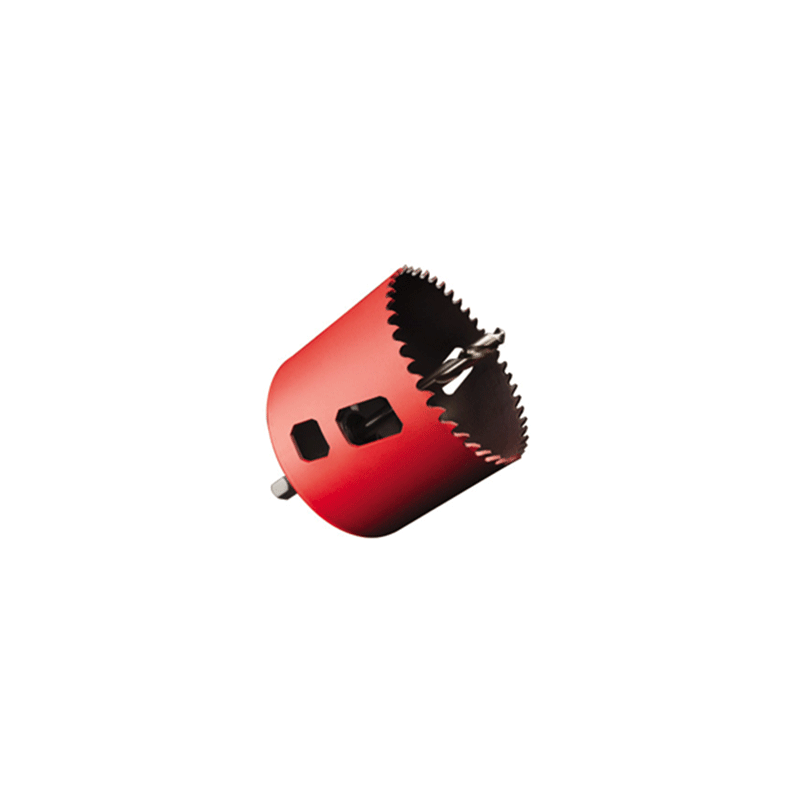

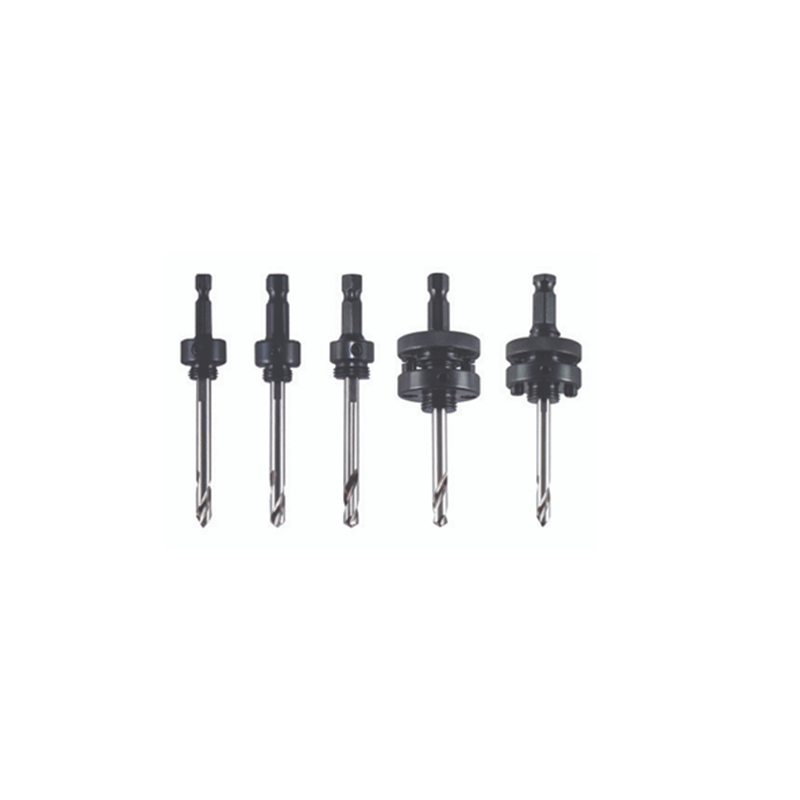

- Holes Saws & Arbors

- Jigsaw Blades

- Reciprocating Blades

- Power Tool Accessories

- Hand Tools

FEMI ABS NG160 BANDSAW BLADE 8/12 TPI

Specifications :

- Blade Construction — Welded Bi-Metal Band With 8% Cobalt

- Blade Length – 1735 mm

- Blade Width – 12.7 mm – 1/2 inch

- Blade TPI – 8 / 10 Variable tpi

- Blade Thickness – 0.64 mm – 0.025 inches

£23.95 Original price was: £23.95.£21.99Current price is: £21.99. ex VAT

30 in stock

M42 Bi Metal Bandsaw Blades manufactured by M K Morse the market leaders in bandsaw blade technology. Morse M42 Blades are engineered with Special high speed steel teeth edges and attached to a patented alloy steel backer for optimum cutting performance resulting in higher heat and wear resistance. M42 Blades offer durability for higher production speeds on difficult to machine solids and heavy walled structures.

Features & Benefits

- Rugged bi-metal construction with hardened M42 teeth and tool steel fatigue resistant backer

- Used on medium to heavy production machines to cut solids and heavy-walled structures

- High heat and wear resistance increase blade life

- Handles hard to machine materials like stainless steel, Inconel, Monel

- Variable pitch teeth can handle a wider range of cross sectional sizes

- High wear and heat resistance

WHY BUY MORSE BLADES ?

Manufactured in Morse’s advance manufacturing plant in the USA. Featuring annealed welds to prevent brittleness. These industrial standard blades have a minimum gauge of 0.64 mm which increases to 1.10 mm as the width as the blade increases (unlike inferior quality blades using 0.36 mm), this result in a blade that consistently cuts straighter and for longer due to its hardened tooth tips.

Applications

Alloy Steels, Mould Steels, Carbon Steels, Structural Steels, Stainless Steel, Inconel, Solids and heavy-walled structures,

| Weight | 200 g |

|---|---|

| Blade Length | |

| Blade width | |

| Blade TPI | |

| Portable Bandsaw Model | |

| Pack Size |

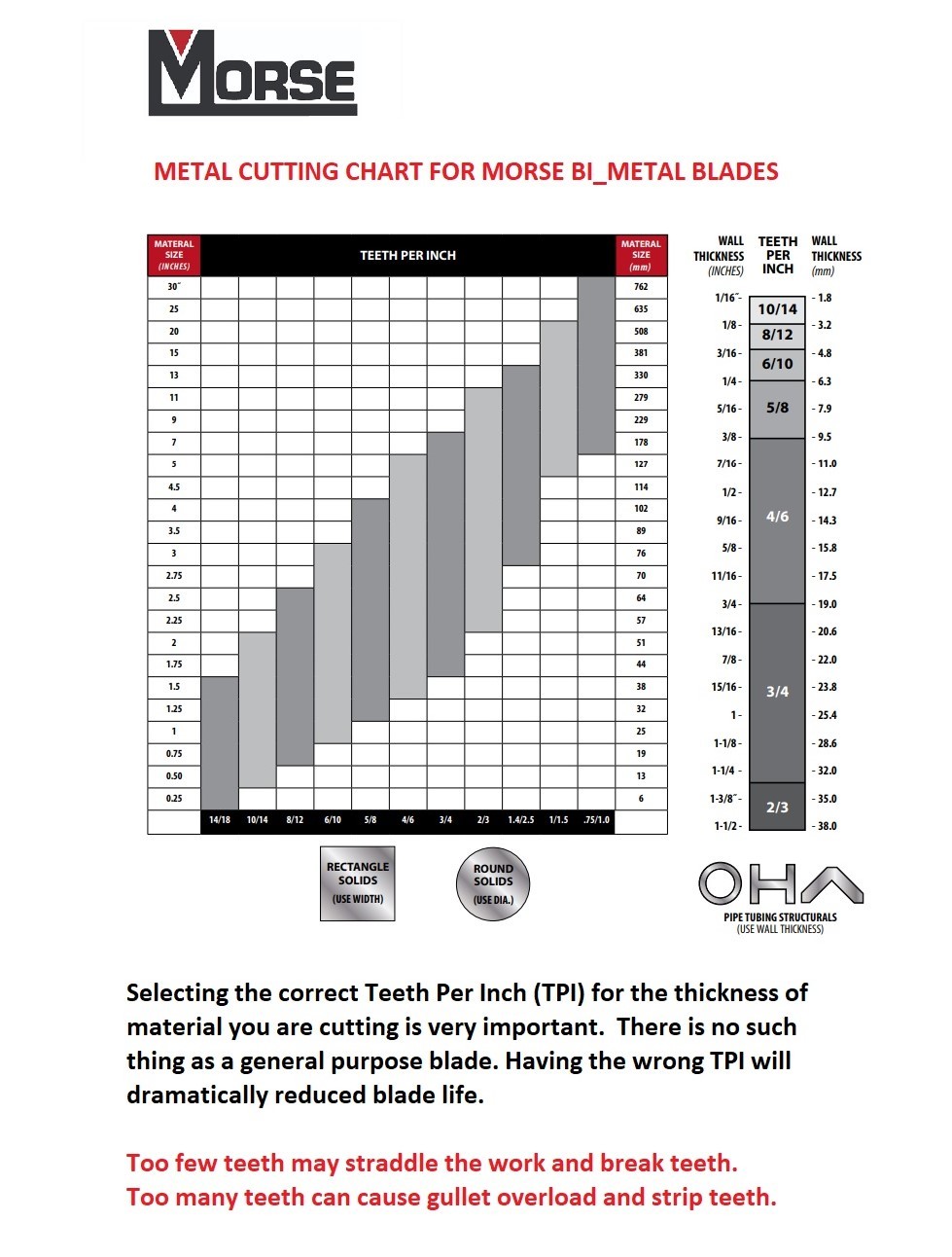

Metal Blade Selection Guide

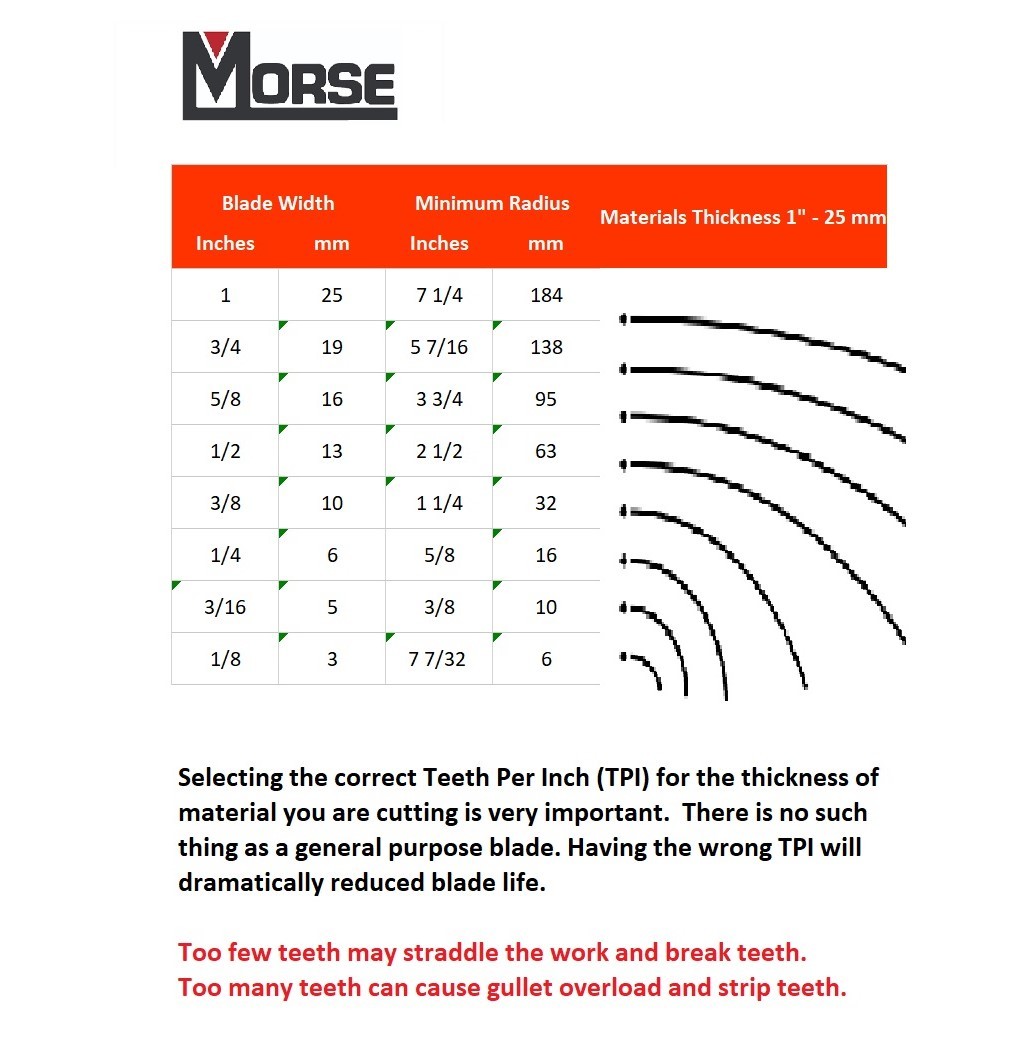

Radius Cutting Chart

Related products

£23.95 Original price was: £23.95.£16.00Current price is: £16.00. ex VAT

£24.00 Original price was: £24.00.£12.00Current price is: £12.00. ex VAT