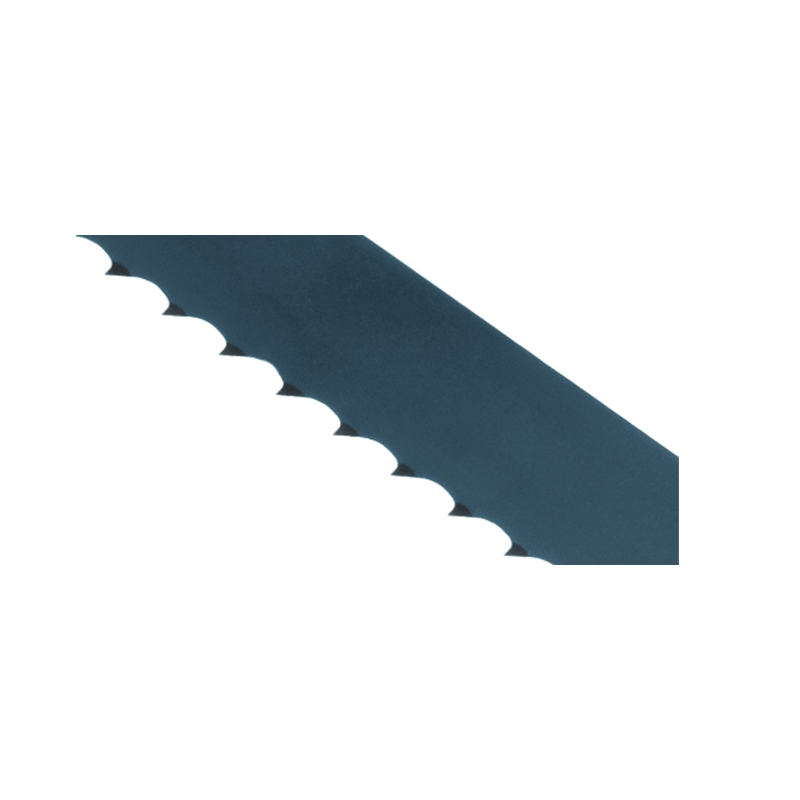

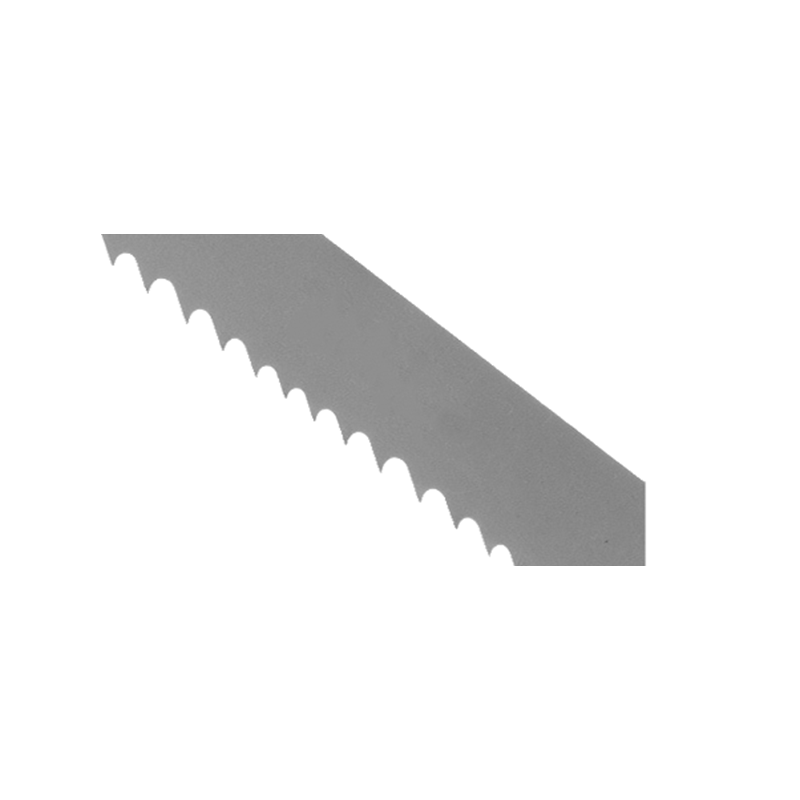

FEMI 787 XL ALLROAD M42 BANDSAW BLADE 8/12 TPI

Manufactured using Morse’s advanced manufacturing techniques, these saw blades feature special high-speed steel tooth edges attached to a patented alloy steel backer. Engineered for optimum cutting performance, they offer higher heat and wear resistance, resulting in exceptional durability and cost-per-cut savings over other saws. The variable pitch tooth design enables these blades to cut a wider range of cross-sectional sizes while reducing vibration. Suitable for both professionals and keen hobbyists.

Features & Benefits

- Rugged bi-metal construction with hardened M42 teeth and tool steel fatigue-resistant backer

- Used on medium to heavy production machines to cut solids and heavy-walled structures

- High heat and wear resistance increase blade life

- Handles hard-to-machine materials like stainless steel, Inconel, Monel

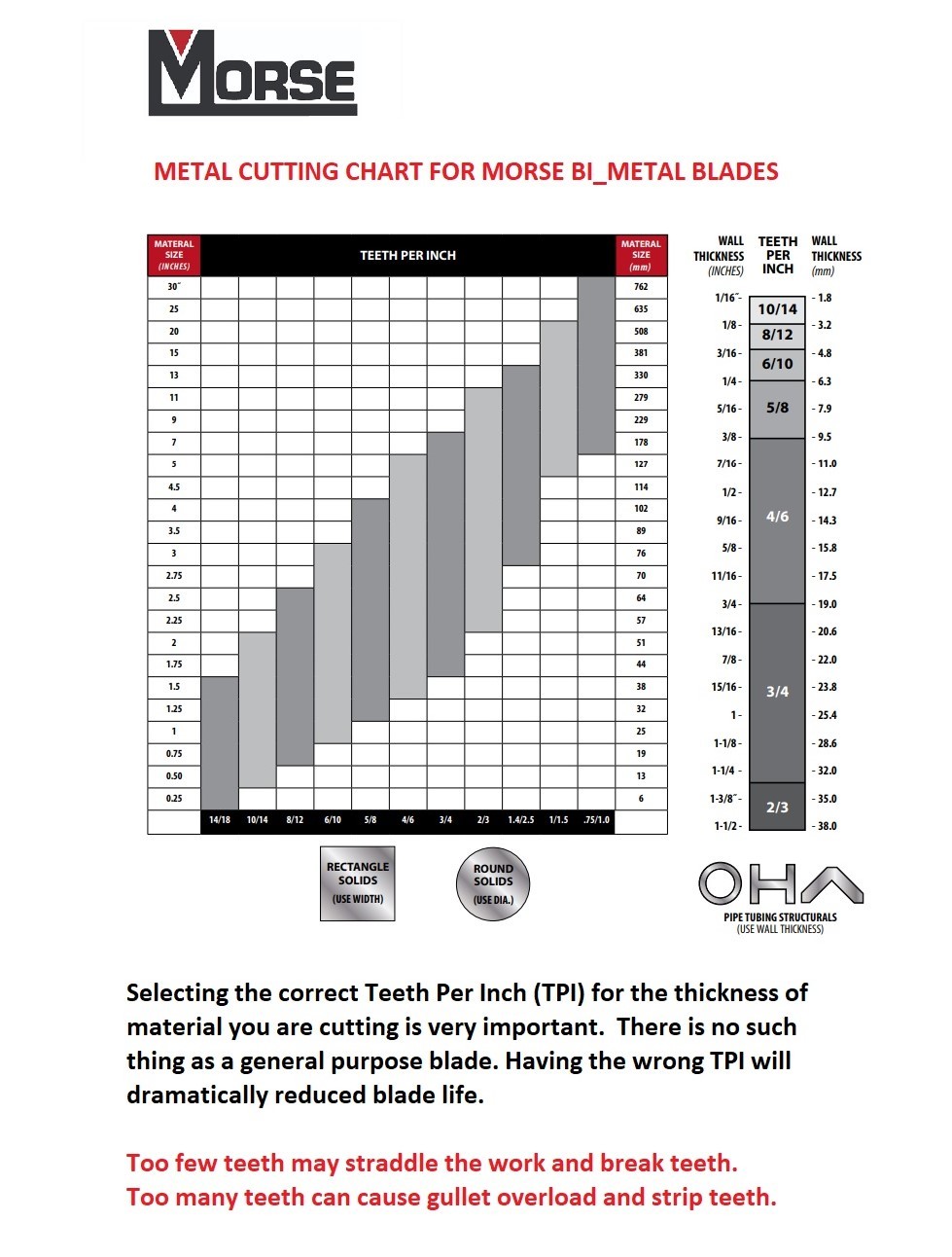

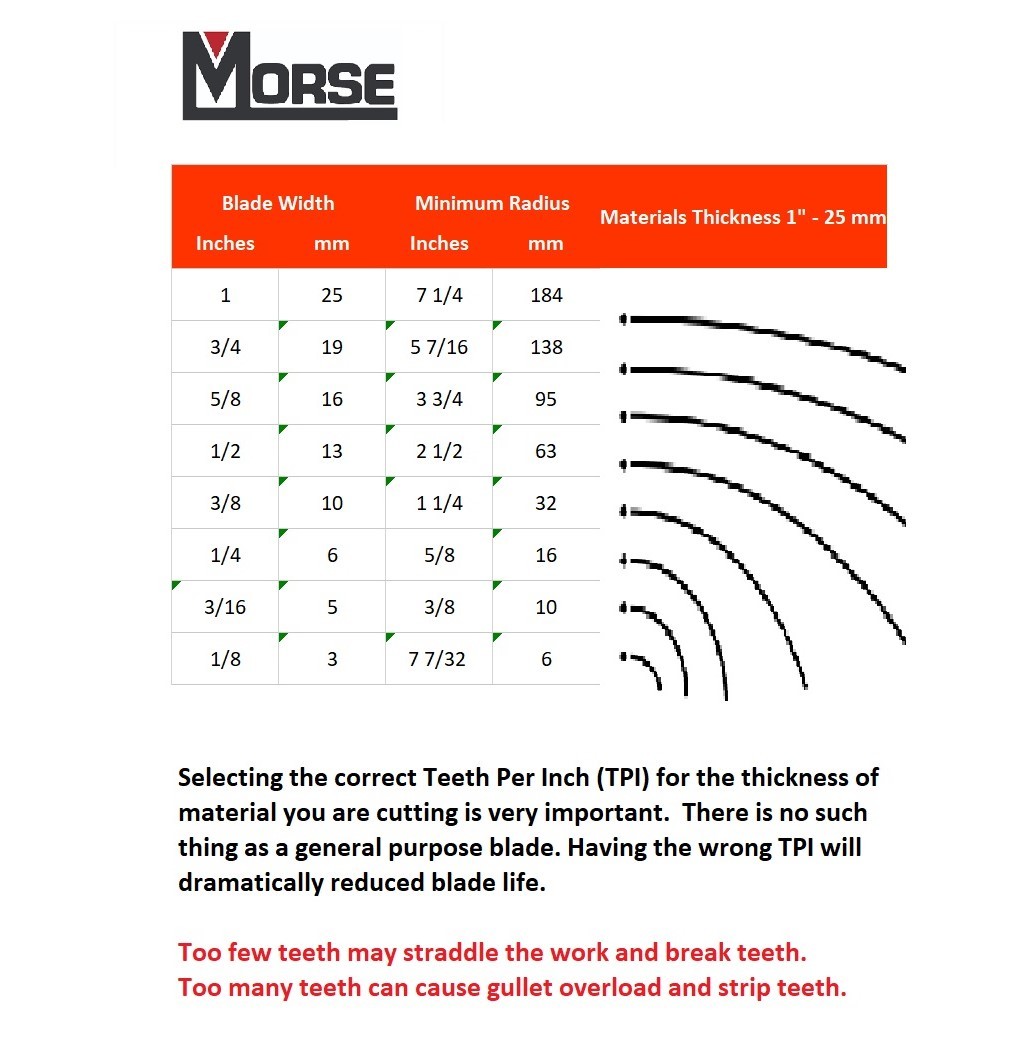

- Variable pitch teeth can handle a wider range of cross-sectional sizes

- High wear and heat resistance

WHY BUY MORSE BLADES ?

Manufactured in Morse’s advanced manufacturing plant in the USA. It features annealed welds to prevent brittleness. These industrial standard blades have a minimum gauge of 0.64 mm which increases to 1.10 mm as the width of the blade increases (unlike inferior quality blades using 0.36 mm), this results in a blade that consistently cuts straighter and for longer due to its hardened tooth tips.

Applications

Alloy Steels, Mould Steels, Carbon Steels, Structural Steels, Stainless Steel, Inconel, Monel, Solids and heavy-walled structures,